The world of machinery is constantly evolving with innovative technologies and intricate systems. As a user, navigating complex machinery can sometimes feel like decoding encrypted codes.

Guess what can help – a comprehensive user manual tailored specifically for machinery. It helps eliminate the pain points and risks associated with inadequate guidance and scattered information.

In this blog, we will dive deep into creating an exceptional user manual for machinery, explore its benefits, and discuss the steps to create it.

What Is a User Manual for Machinery?

A user manual for machinery provides detailed instructions and guidance on safely and effectively operating and maintaining a specific piece of machinery or the entire machine.

It serves as a comprehensive reference guide for users, helping them understand the machinery’s functionality, features, and proper usage.

It usually includes sections like an introduction, safety guidelines, machine components and controls, step-by-step operating instructions, troubleshooting tips, maintenance procedures, and contact information for customer support.

It would also include safety precautions to ensure operators understand the potential hazards and how to prevent accidents while using the machine.

For example, consider a user manual for a CNC (Computer Numerical Control) milling machine. This manual would provide a detailed instruction manual on how to set up the machine, load materials, program the desired cut, operate the machine controls, and perform routine maintenance tasks such as cleaning and lubrication.

Related blog: 12 Best User Manual Creator Tools

What Is the Importance of a User Manual for Machinery?

A user manual for machinery is essential for ensuring the equipment’s safe, efficient, and effective operation. Let’s discuss these in detail.

Ensures Safe Operation

One of the primary purposes of a user manual is to ensure the safe operation of the machinery. It provides detailed instructions on safety precautions, highlighting potential hazards and risks.

By following the guidelines and safety measures outlined in the manual, operators can minimize the chances of accidents, injuries, and damage to the machinery.

Enables Proper Equipment Usage

A user manual provides detailed information on how to use the machinery correctly.

It covers topics like machine components, controls, and their functions. This enables operators to understand the equipment’s capabilities and limitations, improving efficiency and preventing misuse that could lead to downtime or equipment failure.

Read More: Free User Manual Creator

Helps in Troubleshooting & Maintenance

User manuals often include troubleshooting sections to help operators identify and resolve common issues.

They also outline regular maintenance tasks and schedules necessary to ensure the machinery’s optimal performance and longevity.

Following the maintenance guidelines will help prevent breakdowns, reduce downtime, and extend the equipment’s lifespan.

Improves Efficiency

An in-depth user manual aids operators in utilizing the machinery more effectively.

The manual lets users learn the most efficient ways to set up, calibrate, and operate the equipment by providing step-by-step instructions and operational tips. This leads to increased productivity, reduced errors, and improved overall performance.

Read More: How to Create User Manuals for Electronics

Facilitates Standardization

User manuals are crucial in ensuring standardized operation across different users and shifts.

Companies can establish uniform practices and procedures for operating the machinery by having a comprehensive manual. This reduces variations in performance and helps maintain consistent quality and output.

Read More: How to Create User Manual for Corporate Administrators

Acts as Reference & Training Guide

A user manual serves as a valuable reference tool for both new and experienced operators.

It acts as a guide to refresh knowledge, clarify doubts, and train new staff members on correctly operating the machinery. This promotes a smoother learning curve, more effortless knowledge transfer, and reduces reliance on individual expertise.

Read More: Create a User Manual in Word

How to Create a User Manual for Machinery

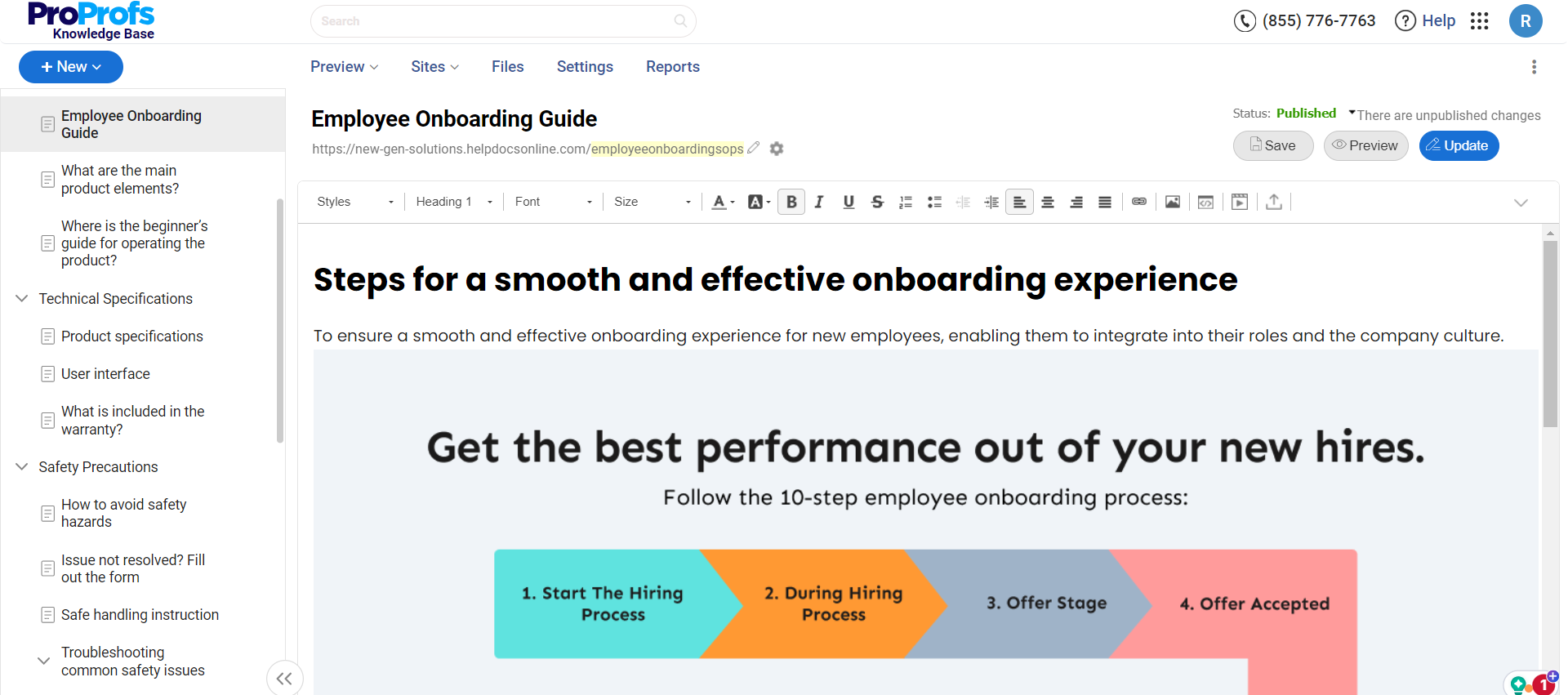

To ensure that your user manual is comprehensive, accurate, and user-friendly, you must follow these steps to create one.

Gather Information

Start by gathering as much information as possible about the machinery, including its features, components, and operational instructions.

You can gather this information from various sources like product manuals, engineering specifications, and technical documentation.

Read More: How to Do Version Control for User Manuals?

Determine the Structure

Decide on the manual’s structure and format depending on the machinery’s complexity and size.

Consider breaking the manual into sections, like an introduction, safety guidelines, machine components and controls, step-by-step operating instructions, troubleshooting tips, and maintenance procedures.

Write & Edit the Instructions

Write the content for each user manual section using clear and concise language.

Ensure that the information is easy to follow, accurate, and consistent throughout the manual. Edit the content for flow, grammar, spelling, and punctuation.

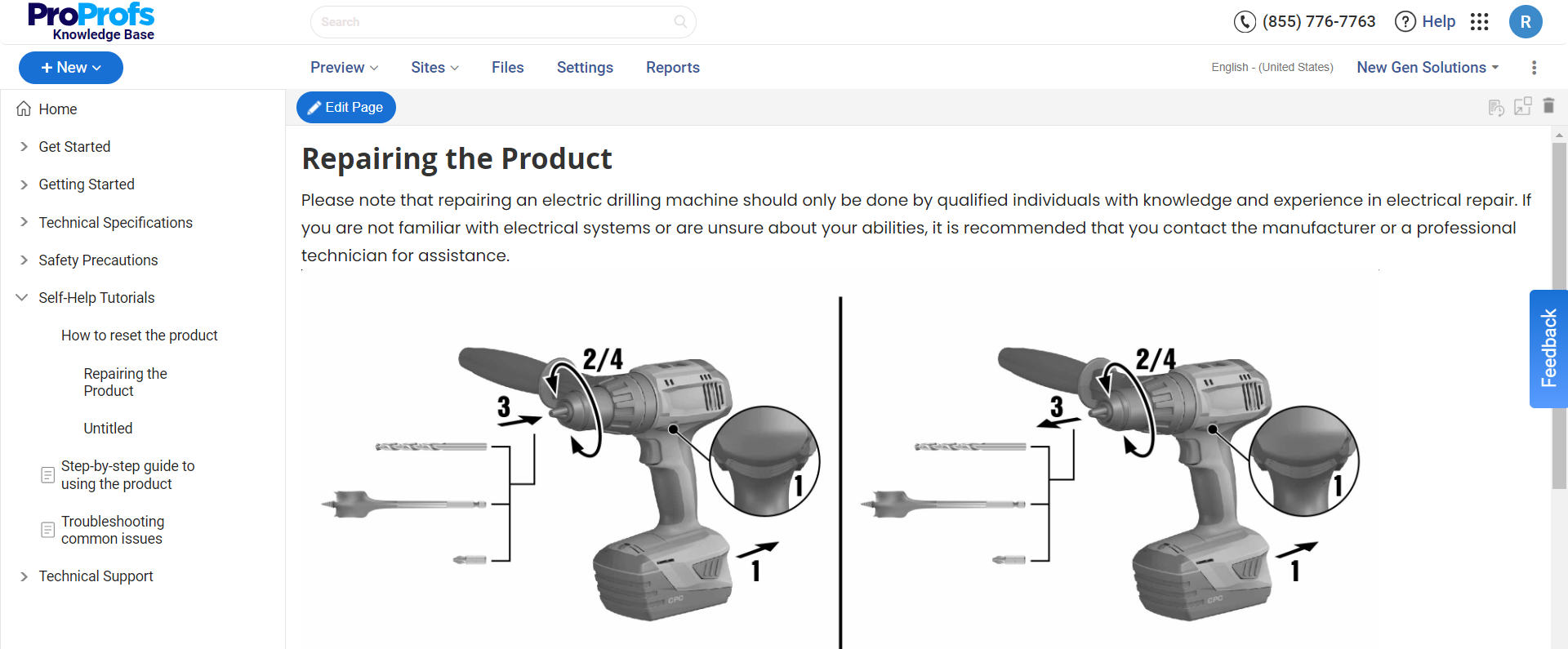

Include Visuals

Incorporate visual aids like diagrams, illustrations, photographs, and flowcharts to assist with understanding the instructions. Ensure that the visuals are clear and of good quality.

Organize Steps

Ensure that the steps involved in the operating instructions are organized and easy to follow.

Use a logical sequence with numbered steps, bullet points, or other visual aids to break down the process.

Test the Manual

Before finalizing the manual, test it by having an individual unfamiliar with the machinery use the manual as their sole reference to operate the equipment.

This will help identify any gaps in the instructions or ambiguities in the language.

Revise & Finalize

After successfully testing the manual, incorporate feedback from the test and make any necessary revisions.

Proofread the content again to ensure accuracy and clarity, then finalize the manual.

Publish the Manual

Publish the manual in either a digital or print format, depending on the circumstances of the machinery and its intended user group.

Ensure you provide ongoing access to the manual in case of updates or revisions.

Create User Manuals for Machinery to Ensure Safety & Efficiency

Creating a user manual for machinery is crucial to ensure safety and efficiency in the operation of the equipment. By providing comprehensive instructions, safety guidelines, troubleshooting tips, and maintenance procedures, these manuals empower operators to use the machinery correctly and minimize the risks of accidents, injuries, and equipment damage.

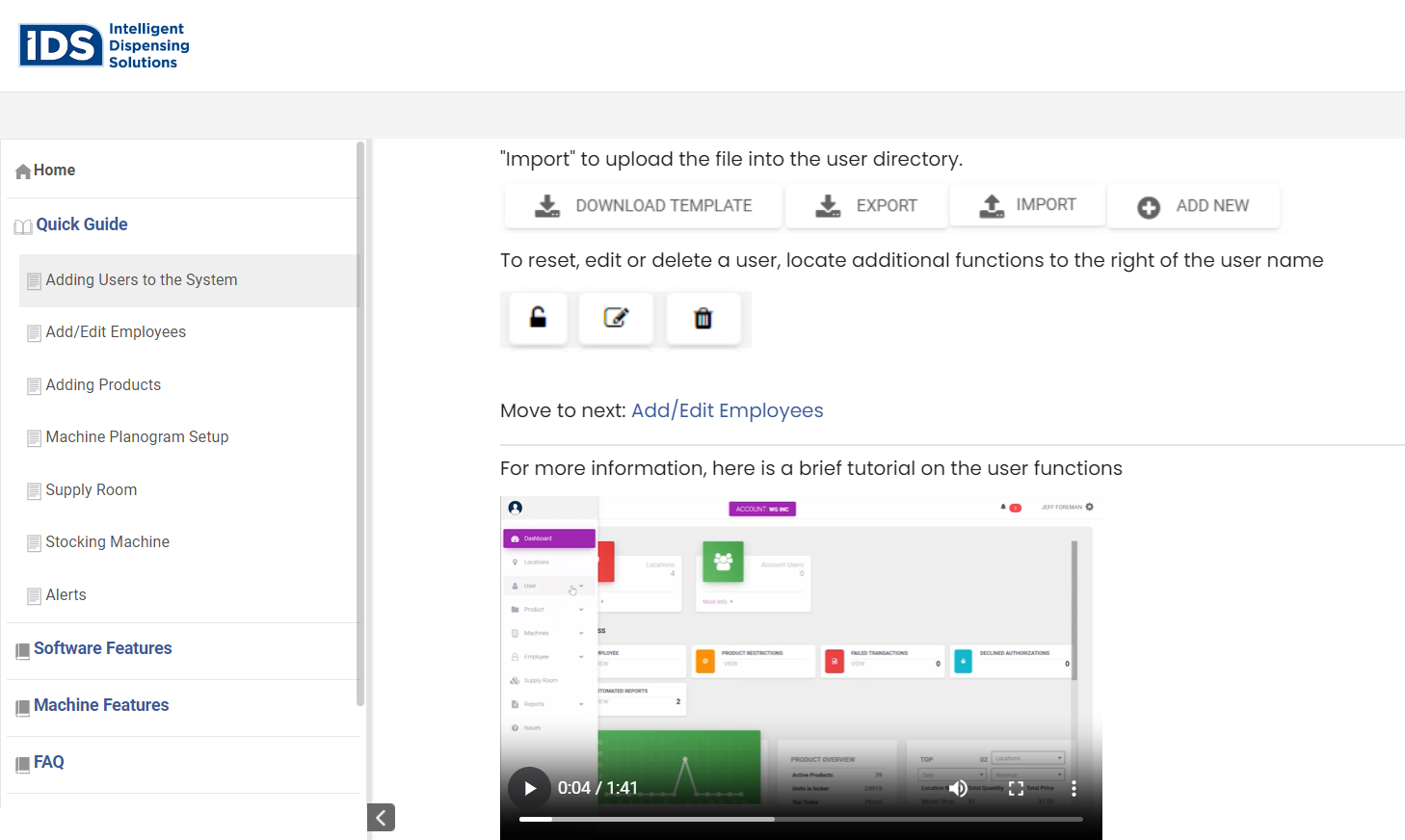

ProProfs Knowledge Base can help you create extensive user manuals for machinery with its AI-enabled text editor and thoughtful user manual templates for quick, error-free content authoring.

Users can engage in real-time conversations, share insights, and refine their content collectively. It also enhances the user experience with a Google-like search experience for readers.

Moreover, in-depth analytics give a bird’s eye view of your knowledge base activity. At a single glance, you can know the total searches, number of articles created, total reads, etc. Get started with the tool today.

FREE. All Features. FOREVER!

Try our Forever FREE account with all premium features!